Optimizing Cost-Effectiveness With Advanced Pipeline Services: a Comprehensive Guide

In the progressing landscape of pipeline management, organizations are significantly looking for ways to improve cost-effectiveness. Advanced pipeline solutions offer a variety of remedies that promise improved operational performance and reduced upkeep expenditures. The assimilation of new modern technologies and strategies presents both possibilities and difficulties. Comprehending these aspects is vital for making best use of the benefits. What particular methods can companies embrace to navigate this intricate setting?

Recognizing Advanced Pipeline Services

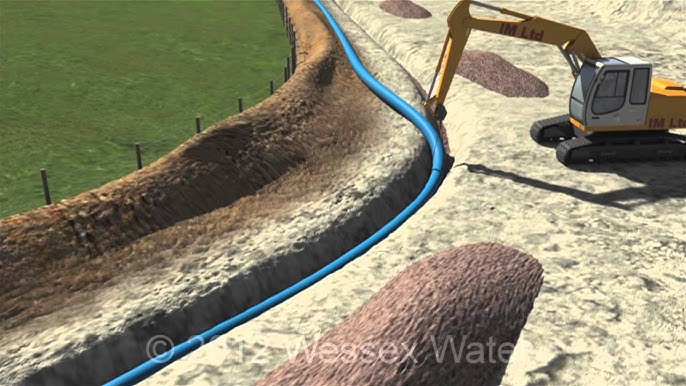

As markets significantly count on effective fluid transportation systems, comprehending sophisticated pipeline services comes to be necessary. These services incorporate a variety of tasks, consisting of the layout, building and construction, maintenance, and operation of pipeline networks. Business involved in advanced pipeline solutions concentrate on enhancing efficiency and guaranteeing safety, commonly making use of specialized expertise and strategies to take care of intricate systems.

One vital aspect is the analysis of pipeline stability, which involves normal assessments and checking to identify potential issues prior to they rise. In addition, the execution of innovative materials and construction methods enhances resilience and minimizes ecological impact. Properly performed pipeline services add to lowered downtime and operational costs, making them important for organizations in markets such as oil, gas, and water circulation. Ultimately, a thorough understanding of these solutions allows business to make enlightened choices, guaranteeing the seamless motion of fluids while adhering to governing criteria and market ideal practices.

Key Technologies Driving Cost-Effectiveness

Countless crucial modern technologies are boosting cost-effectiveness in advanced pipeline solutions. Automation stands apart as an essential chauffeur, making it possible for remote surveillance and control that decreases labor prices and reduces human mistake. The assimilation of Web of Points (IoT) devices enables real-time data collection, assisting in proactive decision-making and maximizing resource allotment. Advanced materials, such as composite pipelines, are significantly utilized for their sturdiness and resistance to corrosion, leading to reduced replacement and maintenance costs with time.

Moreover, data analytics plays a considerable function in recognizing inadequacies and anticipating potential failures, permitting targeted treatments as opposed to covering upkeep approaches. Additionally, equipment learning algorithms can boost predictive maintenance versions, better minimizing functional expenses. Together, these modern technologies foster a more efficient and cost-effective method to pipeline management, making certain that drivers can maximize their investment while maintaining security and compliance criteria

Approaches for Minimizing Maintenance Expenses

Implementing reliable strategies for reducing upkeep expenses in pipeline solutions is necessary for enhancing total operational efficiency. Among the main methods entails adopting anticipating maintenance strategies, which take advantage of information analytics to expect concerns before they escalate. By utilizing sensing units and keeping an eye on systems, operators can recognize prospective problems, enabling prompt treatments that reduce pricey fixings.

An additional essential technique is to systematize devices and components, which simplifies stock management and minimizes training costs for maintenance employees. Routine training programs additionally encourage personnel with the necessary skills to execute maintenance jobs extra efficiently.

Enhancing Safety And Security Criteria in Pipeline Monitoring

While the integration of sophisticated technologies in pipeline administration has considerably boosted operational performance, boosting security criteria remains an essential priority. Companies need to apply extensive safety protocols to reduce risks related to pipeline procedures. Regular evaluations, making use of both drones and clever sensing units, can identify potential risks before they rise into significant issues.

Training workers in emergency situation response and safety procedures additionally adds to a more secure working environment. Additionally, adopting robust monitoring systems aids in the early detection of leakages or structural weaknesses, permitting timely interventions.

Furthermore, compliance with sector laws and best practices assurances that precaution are not only efficient however additionally standardized across operations. Involving with stakeholders, including neighborhood neighborhoods, promotes transparency and constructs trust fund, boosting overall safety perceptions.

Inevitably, focusing on security in pipeline management not only protects employees and the atmosphere yet likewise aligns with affordable functional methods.

Enhancing Workflow for Greater Performance

Enhancing pipeline operations requires a tactical technique that minimizes waste and maximizes efficiency - Midland pipeline construction company. By carrying out advanced modern technologies such as automation and data analytics, business can enhance their operational performance. These tools allow real-time surveillance of pipeline conditions, permitting timely treatments that prevent expensive downtime

Systematizing procedures also contributes to structured procedures. By adopting constant methods for upkeep and evaluations, organizations can lower irregularity and improve reliability in their pipeline services. Furthermore, staff member training plays a crucial role; well-informed workers are better furnished to implement tasks efficiently and safely.

Partnership with seasoned provider can use added insights into finest methods, allowing firms to fine-tune their functional structures. Ultimately, a concentrate on continuous enhancement warranties that pipeline operations stay active and responsive to altering needs, promoting long-lasting sustainability and cost-effectiveness in the sector.

Often Asked Questions

What Certifications Should I Seek in a Pipe Solutions Supplier?

When choosing a pipeline providers, one need to think about qualifications such as market accreditations, experience, security records, technical knowledge, customer references, and compliance with regulatory criteria to guarantee reputable and efficient solution shipment.

How Can I Analyze the ROI of Advanced Pipeline Services?

To analyze the ROI of advanced pipeline solutions, one ought to assess cost savings, performance improvements, and boosted earnings generation. Contrasting these metrics against Creek Pipe Midland TX first investments and continuous operational expenses will provide a clearer economic image.

Are There Any Kind Of Industry Qualifications for Pipeline Solution Technologies?

What Are the Ecological Effects of Advanced Pipeline Services?

How Commonly Should Pipeline Equipments Be Examined for Effectiveness?

Pipeline systems ought to be evaluated for efficiency at the very least each year (Midland oilfield pipeline services). Normal evaluations help identify potential concerns, enhance performance, and warranty compliance with regulations, inevitably adding to improved dependability and decreased operational costs in the lengthy run